Environmentally friendly material

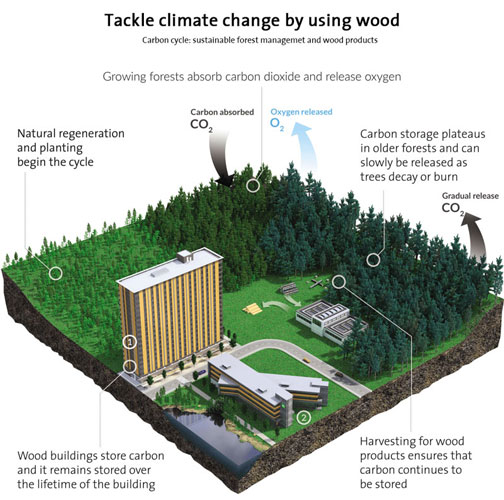

In any of these cases, the carbon cycle begins again as the forest is regenerated, either naturally or by planting, and young seedlings once again begin absorbing carbon.

Manufacturing wood into products requires far less energy than other materials, and very little fossil fuel energy. Most of the used energy comes from converting residual bark and sawdust to electrical and thermal energy, adding to wood’s light carbon footprint. This is particularly interesting to policymakers and design professionals alike. They realise the positive impact forests and forest products have on greenhouse gases and work towards it.

Wood from British Columbia (B.C.), Canada is procured from sustainably managed forests and third-party certified to forest standards such as PEFC / FSC, assuring Indian customers of its environmental credentials.

Life-cycle assessment of wood (LCA)

The goal of the green design is to achieve sustainability by designing and building structures that use less energy, water and materials, and minimize impacts on human health and the environment.

Life cycle assessment (LCA) supports this by providing an assessment of the resource consumption — including energy, emissions and waste — throughout the building’s life. It means adding up the inputs and outputs for every framing member, panel, fastener, finish material, coating and other materials used in the building.

LCA is accepted around the world and is a powerful tool for illustrating the full life-long environmental impacts of choosing one building material over another. It is incorporated into many green building rating systems.