What is life cycle assessment?

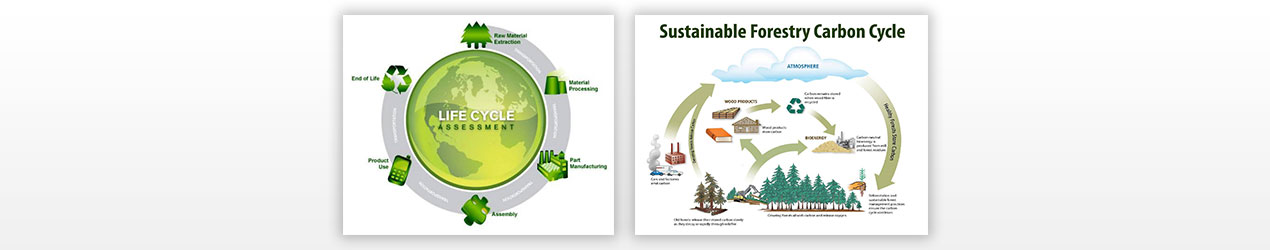

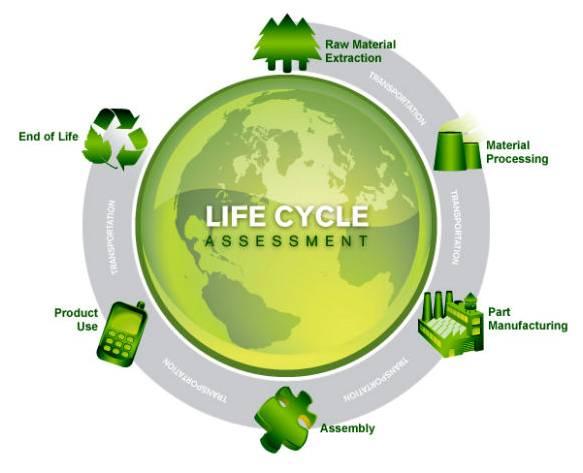

Life cycle assessment (LCA) is a tool for the systematic evaluation of the environmental aspects of a product or service system through all stages of its life cycle. LCA provides an adequate instrument for environmental decision support. LCAs can provide a broad outlook on environmental concerns by:

- Compiling an inventory of relevant energy and material inputs and environmental releases

- Evaluating the potential impacts associated with identified inputs and releases

- Interpreting the results to help make a more informed decision

Stages in the life cycle of a product

Why is it important to designers and architects?

Life cycle assessment is a performance-based approach to assessing the impacts building choices have on the environment. LCA can be used to analyze potential impacts of a product or structure at every stage of its life, including:

- Fossil fuel depletion

- Other non-renewable resource use

- Global warming potential

- Acidification

- Stratospheric ozone depletion

- Ground level ozone (smog) creation

- Eutrophication

- Hazardous and non-hazardous waste

Life cycle assessment is accepted around the world as a way to evaluate and compare the environmental impacts of different building materials, products and complete structures over their lifetime – from resource extraction through manufacturing, transportation, installation, building operation, decommissioning and eventual disposal. Choice of building material based on its LCA plays an important part in green rating points of a structure.

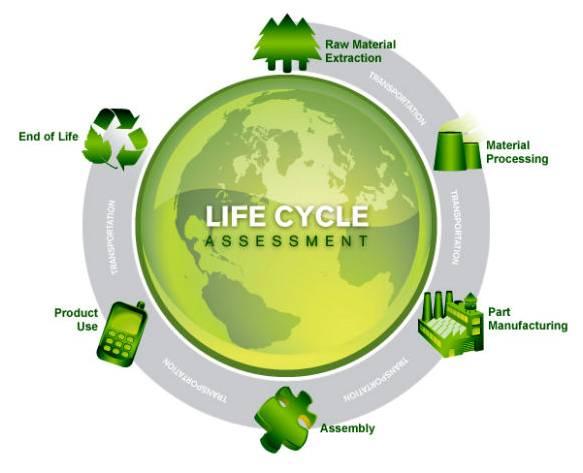

Life cycle of wood from sustainably managed forests

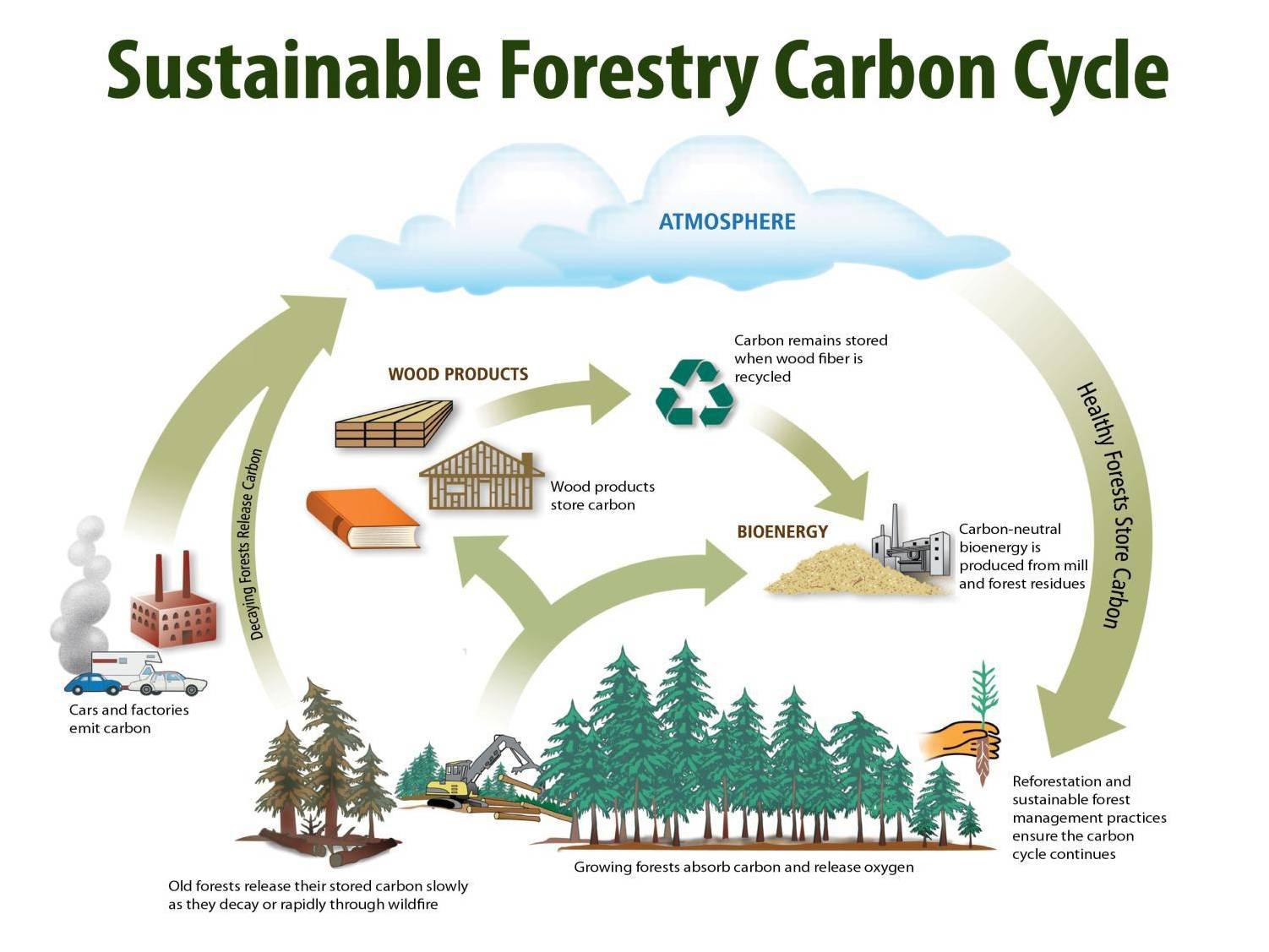

Canadian Wood - Adopted from California forest products commission carbon dioxide from the atmosphere gets absorbed by growing forests and stored for the entire life cycle of the tree. Even after being harvested wood continues to store carbon for its entire life till the point of decay. Production of wood creates residue in the form of sawdust, which can be used as carbon-neutral fuel. Reforestation and

sustainable forest management ensures that the carbon cycle continues and carbon dioxide continues to be taken out of the atmosphere.

Manufacturing of wood products requires less total energy, and in particular less non-renewable (fossil) energy, than the manufacturing of most a

-lternative materials. The drying process accounts for most of the energy used in the manufacture of wood products. Wood processing residues (such as sawdust) are commonly used to fuel the drying, avoiding depletion of fossil fuels.

Wood as a carbon neutral building material

When sustainable forestry is practiced, trees, and the carbon they contain, are replenished as they are harvested. Carbon is obtained from atmospheric CO2 via photosynthesis, becoming part of wood as a tree grows in height and diameter. Timber-based building products continue to store carbon absorbed during the tree’s growing cycle for as long as they are in use. The capacity of trees to absorb and store carbon can be factored against the carbon emissions incurred during drying, processing, and transporting wood products. The result is a very low carbon building material.

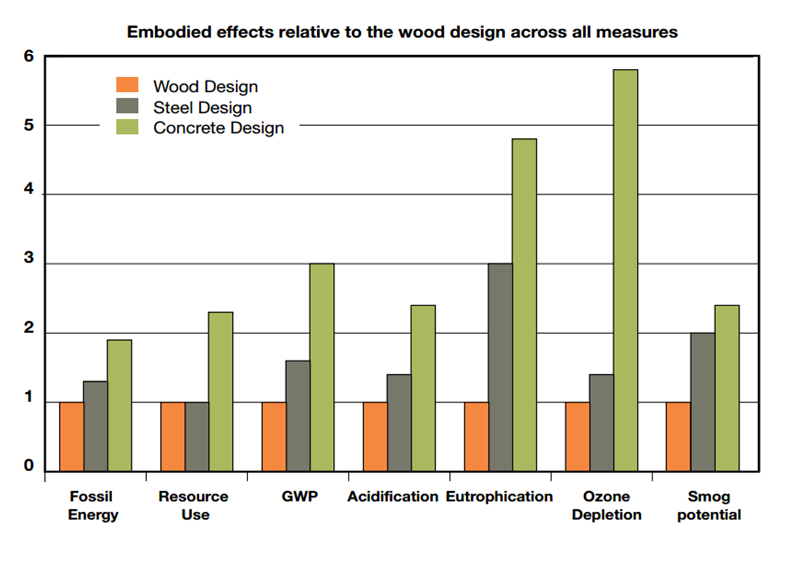

Wood v/s steel and concrete

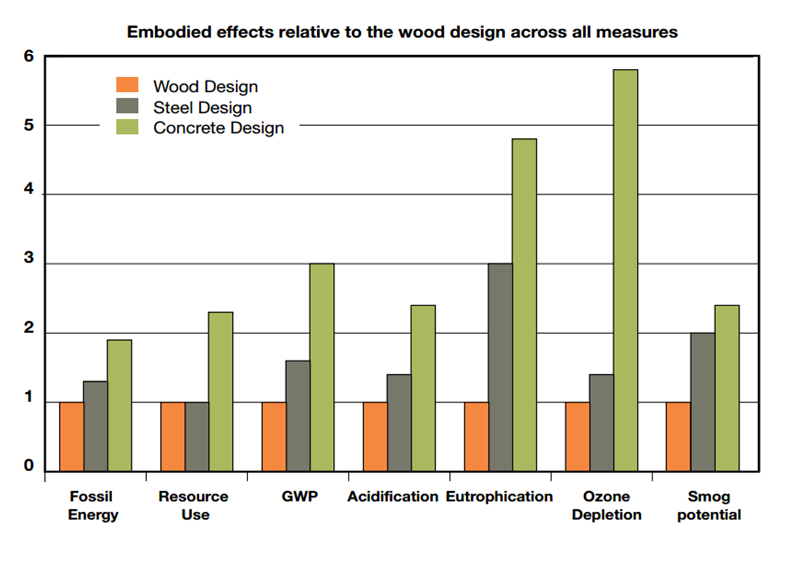

An independent study compared the environmental impact of wood, steel and concrete. Three hypothetical commercial buildings (wood, steel, and concrete) of identical size (40,000 sqft) and configuration were compared. Assessment results were summarized into seven key measures covering fossil energy consumption, weighted resource use, global warming potential, and measures of potential for acidification, eutrophication, ozone depletion, and smog formation. The results were quite stark as evident in the graph below

Source : Dovetail Partners using the Athena Eco-Calculator (2014)

On each of the seven parameters, wood had a significantly lower environmental impact as compared to its counterparts. This study does not even take into account the physical and emotional benefits wooden spaces bring to their inhabitants.

Today with attention turning to sustainable design and LCA-based tools that identify the lowest impact alternatives, more designers are getting familiar with the environmental advantages of wood and wood products. As a result, wood will be a building material of choice for a growing range of applications The important point to consider is that wood products should come from sustainably managed sources.

Stages in the life cycle of a product

Stages in the life cycle of a product

Canadian Wood - Adopted from California forest products commission carbon dioxide from the atmosphere gets absorbed by growing forests and stored for the entire life cycle of the tree. Even after being harvested wood continues to store carbon for its entire life till the point of decay. Production of wood creates residue in the form of sawdust, which can be used as carbon-neutral fuel. Reforestation and sustainable forest management ensures that the carbon cycle continues and carbon dioxide continues to be taken out of the atmosphere.

Manufacturing of wood products requires less total energy, and in particular less non-renewable (fossil) energy, than the manufacturing of most alternative materials. The drying process accounts for most of the energy used in the manufacture of wood products. Wood processing residues (such as sawdust) are commonly used to fuel the drying, avoiding depletion of fossil fuels.

Canadian Wood - Adopted from California forest products commission carbon dioxide from the atmosphere gets absorbed by growing forests and stored for the entire life cycle of the tree. Even after being harvested wood continues to store carbon for its entire life till the point of decay. Production of wood creates residue in the form of sawdust, which can be used as carbon-neutral fuel. Reforestation and sustainable forest management ensures that the carbon cycle continues and carbon dioxide continues to be taken out of the atmosphere.

Manufacturing of wood products requires less total energy, and in particular less non-renewable (fossil) energy, than the manufacturing of most alternative materials. The drying process accounts for most of the energy used in the manufacture of wood products. Wood processing residues (such as sawdust) are commonly used to fuel the drying, avoiding depletion of fossil fuels.

Source : Dovetail Partners using the Athena Eco-Calculator (2014)

On each of the seven parameters, wood had a significantly lower environmental impact as compared to its counterparts. This study does not even take into account the physical and emotional benefits wooden spaces bring to their inhabitants.

Today with attention turning to sustainable design and LCA-based tools that identify the lowest impact alternatives, more designers are getting familiar with the environmental advantages of wood and wood products. As a result, wood will be a building material of choice for a growing range of applications The important point to consider is that wood products should come from sustainably managed sources.

Source : Dovetail Partners using the Athena Eco-Calculator (2014)

On each of the seven parameters, wood had a significantly lower environmental impact as compared to its counterparts. This study does not even take into account the physical and emotional benefits wooden spaces bring to their inhabitants.

Today with attention turning to sustainable design and LCA-based tools that identify the lowest impact alternatives, more designers are getting familiar with the environmental advantages of wood and wood products. As a result, wood will be a building material of choice for a growing range of applications The important point to consider is that wood products should come from sustainably managed sources.